|

How to Measure Schedule 40 Ultra Flex PVC Pipe Measure Twice; Buy Once One of the most frequent questions we get, and the reason for almost every product return to our site, is because the “common sense method” of measuring does not really apply when it comes to Schedule 40 flexible PVC pipe. The “Pipe Schedules” were constructed by someone undoubtedly in a bureaucratic position, not one using common sense measuring techniques. It is quite easy to measure across your pipe, but that is where the “easy” ends. So we say, Measure twice, buy once” and you’ll get what you need the first time. Someone once sent us the following email about bureaucracy and specifications (source unknown): RFQ SPECIFICATION WAP-007 PAGE 1 OF 1 PIPING SPECIFICATIONS

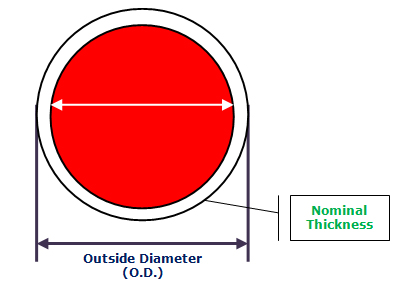

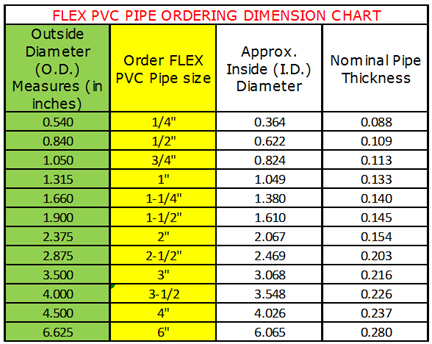

The above proves why bureaucracies don’t do a good job of creating specifications, but unfortunately, flexible pipe sizes are made in accordance with and to the tolerances of the Schedule 40 pipe specifications. The standards or “schedules” and sizes work like this. The outside diameter of a single “nominal” pipe size is kept constant. So when you are buying a fitting for a Schedule 40 pipe, the outside diameter of the pipe and the fitting size will always be the same. This is the reason for the “schedules” – so that fittings and pipe can easily match across a broad spectrum of manufacturing, and within “acceptable” tolerance and standards. So the outside diameter remains constant, and as a result the inside diameter of a pipe will depend on the "schedule" or the thickness of the pipe. The schedule and the actual thickness of a pipe varies with the size of the pipe. WHAT DOES THAT ALL MEAN? OK, let’s cut through the fog here. It means that you need always need to measure the OUTSIDE (O.D.) diameter of your flexible PVC Schedule 40 pipe…

…and then compare that measurement to the following chart in order to order/receive the correct size. We know, this does not pass the “common sense test”, but it’s the way the industry works…and it will keep you from ordering the wrong size flexible PVC pipe! We know this is confusing, if you have questions on what size flexible PVC pipe or fittings to use, call or email us any time! PLEASE NOTE – Flexible PVC pipe is NOT meant to be used with fittings that fit INSIDE the pipe, sometimes called barbed fittings, friction fittings or insert fittings. While these fittings MAY fit and MAY work, we do not recommend their use, nor do we guarantee that our flexible PVC pipe will fit these fittings.

PLEASE NOTE – the sizes listed in the chart above are for reference only, and tolerances in the standard allow for deviations in size and diameter of +/- 10%.

|